CONTACT LENS MEASUREMENT

As contact lens design becomes more complex, a new generation of instrumentation is required to ensure that manufactured lenses meet with the required tolerances and specification.

The Optimec is830 lens imaging system provides a new approach to contact lens metrology. Using the latest technology gives users simple access to comprehensive, non-contact geometric lens data.

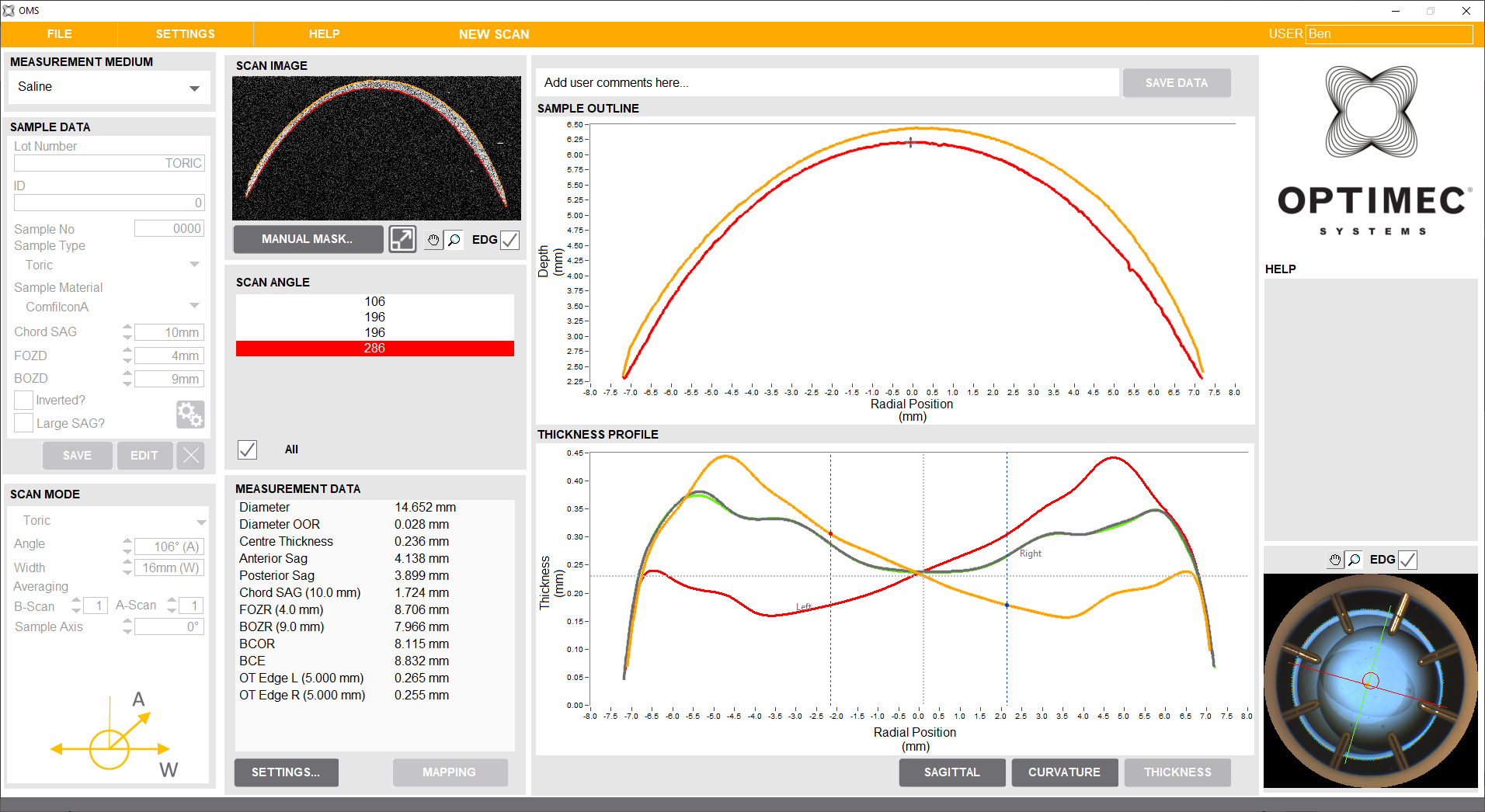

ADVANCED GEOMETRIC MEASUREMENT

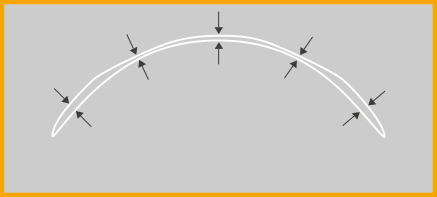

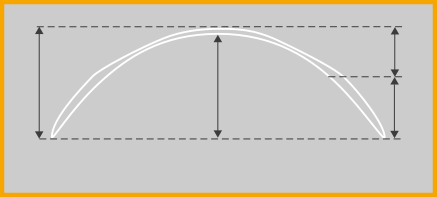

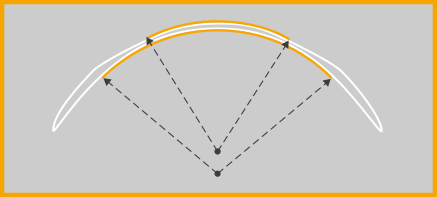

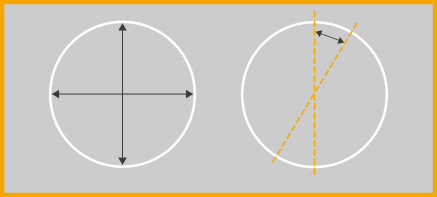

By utilising Optical Coherence Tomography (OCT), we can extract all types of geometric parameters from contact lens samples.

Thickness

Curvature

Sagittal Depth

Diameter

Angular data

Such measurements have previously required multiple instruments and user skillsets, or have been unobtainable by non-destructive methods. Our technology makes all of these easy to extract.

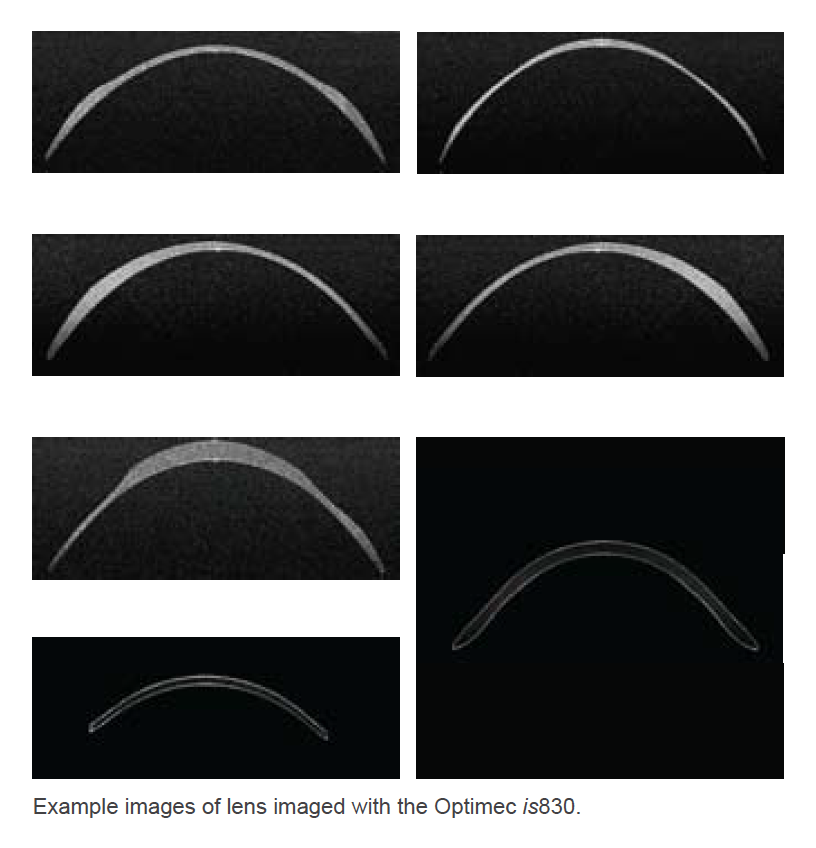

Click on image to enlarge

Delivering essential metrology imaging and data for use across the entire contact lens design and manufacturing process.

Using OCT allows measurement of all types of lenses at multiple stages through the production process.

SOFT LENSES

- Sphericals

- Aspherics

- Torics

- Multifocals

- Cosmetic

RGP LENSES

- Sphericals

- Sclerals

- Aspherics

- Torics

- Multifocals

- Ortho-K

IN PROCESS

- On Mandrel

- In mould

- Hydration process

Design, research and development, quality control and production departments will all benefit from the speed, reliability, capability and repeatability of this new generation of lens metrology instrumentation.

Optimec has a long and proven history of providing simple to use, ‘user friendly’ measurement instrumentation that requires minimal training and set-up time.

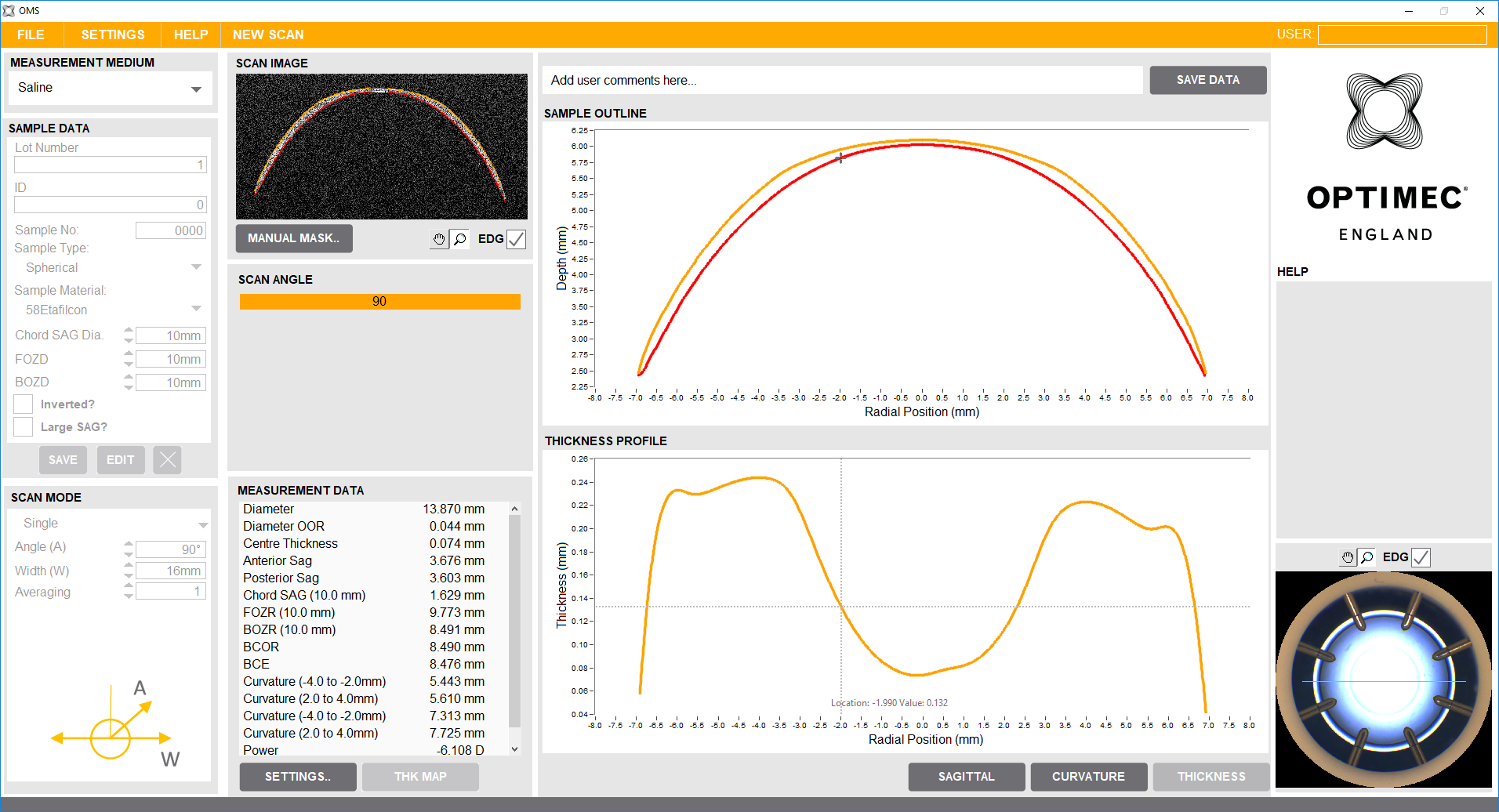

The Optimec is830 imaging and measurement system has been carefully developed with a ‘user friendly’ design philosophy.

By integrating a simple open measurement cell with a clear, easy to use software interface, a new user can be imaging and measuring lenses in a matter of minutes. The lens sample is simply placed into an open cell and positioned with the aid of the on screen camera image. The measurement mode is then selected (e.g.- single scan, toric scan, etc.), and the system then scans the lens, providing detailed lens images.

A comprehensive range of lens types and materials can be imaged and measured (in fluid or in air), including:

- Hydrogel - Silicone Hydrogel - RGP - PMMA - Hybrid

SOFTWARE-DRIVEN SOLUTION

The Optimec is830 OMS Software uses custom designed algorithms that enable the full anterior and posterior surfaces of the sample lens to be defined and measured in less than a second, with the resulting data and measurements being displayed clearly on-screen.

The lens images, measurements and associated data can then be exported as required by the user.

Easy-to-use software and simple-to-navigate screens provide the user with fast access to measurements, lens types and data:

- Materials library - Measurement modes - Lens types - In solution - In air

INDUSTRY-LEADING PRODUCT

Optimec Systems are committed to the continual improvement of the Optimec is830 lens measurement system and to providing excellence in both products and service to our customers.

GET IN TOUCH WITH US TODAY

For more information about our Optimec is830 solutions, or if you would like to request a sample lens report or book an evaluation trial, please get in touch.